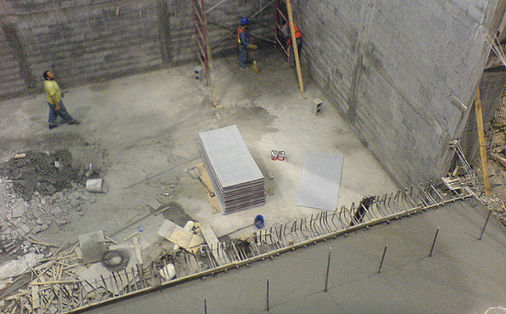

Cimentación Aislada

Ventajas de utilizar nuestros materiales de aislamiento en cimentaciones:

-

Aislamiento predecible desde antes de construir la cimentación debido a que se conoce el comportamiento a la carga/compresión de este material, debido a las pruebas de laboratorio realizadas por Unisorb en USA.

-

Este material tiene la propiedad natural de disipar mayor energía en los impactos por ser acolchonado teniendo un alto coeficiente de amortiguación interna.

-

Su vida útil es mayor a los 60 años y ha sido probado en un sin número de cimentaciones de prensas hasta 6000 ton.

-

No se ve afectado en ninguna de sus propiedades por entrar en contacto con aceites, refrigerantes u otros líquidos de corte utilizados en e ambiente industrial.

-

La prensa y los herramentales se protegen más al disipar energía en la operación, disminuyendo el rebote.

-

Las áreas periféricas a la prensa no se ven afectadas por la operación de la misma.

GK™ Low Frequency Foundation Block

The GK™ Low Frequency Foundation Block is specifically used for isolating equipment where low interfering frequencies are encountered. They are typically used under concrete foundations supporting either source or sensitive machines. The highly specialized rubber compounds used, unique geometrical shape and carefully controlled load deflection characteristics make the GK block an excellent lower cost alternative to installations normally required to reach system natural frequencies as low as 4 Hz. GK™ Blocks are available in load ratings from 4,000 to 18,000 lbs.

Examples of GK™ Low Frequency Foundation Block applications include:

-

Coordinate measuring machines

-

Precision optical equipment

-

Precision grinders

-

Vibrating conveyors

-

Lab equipment

-

Automated equipment or robotics

-

Equipment operating in severe shock and vibration environments

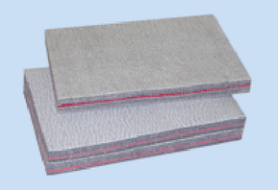

IB-500™ Inertia Block Foundation Isolation Materials

UNISORB® IB-500™ Inertia Block Isolation Materials offer superior performance because they have been specifically engineered to provide optimum compression rates for the inertia block while using standard foundation construction techniques. These products are unaffected by oils, coolants, cutting fluids and other liquids normally found in the industrial environment. IB-500™ Inertia Block Isolation Materials are conservatively rated, providing a life expectancy which typically exceeds that of the machinery being installed.

The materials are manufactured in two densities: A less dense material, designated IB-500-S2, is used to isolate sidewalls of the inertia block; A more dense material, IB-500-B1, is applied to the base surface of the foundation (usually two layers). Both materials are manufactured in 1/2″ thick sheets and are used in layers where greater thickness is desired. The material is available from stock in 3′ x 6′ sheets for fast delivery. Special sizes may be cut to exact dimensions at the factory or on the job site.

The isolation material is protected from moisture migrating from fluid concrete by a water resistant covering which also provides a tough, abrasion and puncture resistant surface.

Although there are several different methods of installation, the proper approach depends primarily on the depth of the inertia block and the condition of the soil. UNISORB® Applications Engineers can offer assistance in determining suitable materials and procedures to meet specific inertia block requirements.